Amyx Manufacturing Company

Amyx Firm Making a Big Hit With Ozarks Ash Shillelaghs by Dale Freeman

News & Leader, January 8, 1950 p. C-3

"They're telling around this sports minded Howell County community how Stan Musial broke a terrific batting slump a couple of seasons back because of a West Plains Company which packs a wallop.

"So the story goes, the Cardinal slugging great couldn't have hit a medicine ball tossed shot-put style by Tallulah Bankhead. And then, of course, Stan decided to switch bats.

"His pick: A shillelagh fashioned by the Amyx Manufacturing Company of West Plains, fourth largest bat makers in the world.

"The result: A mighty wallop, on the first pitch, naturally, which was reported to have lit in the general vicinity of the Mississippi River.

"Whether that Bill Sternish tale is true, or whether that West Plains built bat had anything to do with Stan's homer, the Amyxes won't say.

"But if it is, that was the official start of Amyx Manufacturing Company's war clubs breaking into the big time of major league baseball. And now, what with comfortable orders being sent out to such clubs as the Browns, Cards, Tigers, and Cubs, the father and son team is planning on keeping its bats up there from here on out.

"[The] story of Ozarks-produced bats began back in 1943 when young Orin Amyx and his father, Dr. M. C. Amyx, a dentist and mayor of West Plains, started a small plant for manufacturing juvenile furniture. They were novices from the word go. And tragedy struck the new venture almost from the outset. Fire destroyed everything, plant and materials, only three months after they started production. But they decided to go on and soon constructed an entirely new plant. By the middle of the war, they were turning out considerable juvenile furniture.

"Then the Amyxes received a small order for softball bats because 'they were so hard to get during the war,' young Amyx explains.

"'Our first ones looked so good, we've been at it ever since. Forgot all about the furniture business,' he says.

"And by 1945, the Amyxes, equipped with new lathes and plenty of modern equipment, went into full-scale production. Oddly enough, neither of them knew anything about making bats. Neither had they played professional ball. As 'Doc' Amyx points out: 'I was just a country ball player in my time.'

"[The] only 'name' attached to the Amyx firm came some time ago when Ted Gullic, former major league star and minor league manager, and his brother, Percy, bought stock in the company. Since then, the Amyxes have repurchased all stock.

"Now, manned by a production staff of 15 with young Amyx at its helm, the company turns out between 250 and 300 dozen bats a day, an average of more than 50,000 dozen a year. It's ranked fourth in the world with Louisville Sluggers, of course, leading the pack.

"[The] biggest order for the Amyx Company in those early years, came from the Army. The firm shipped 13 carloads of softball bats overseas. And each carload contained between 10 and 15,000 you-know-whats.

father and son both class the business as still just a 'comer',

"But right now, they're working on one of the biggest requests they'd ever hoped to get, an order for 16,000 dozen bats for a variety store chain. Acquisition of that whopping order, and the fact that this is the company's big season anyway, has left the firm so short-staffed it may have to add more employees.

"The Amyxes aren't about to be caught short-materialed, however. They keep some 5,000 pieces of raw material on hand, it's dried nine months before it's used, and employ four extra sawmills, besides their own, to keep the production line going.

"That raw material will be turned in to at least five distinctive styles of baseball bats, several different grades of softball clubs, various miniature ones and, to top it all, two sizes of rolling pins.

"Virtually all bats are made from ash, obtained from the immediate vicinity of West Plans, and some hickory, used only in making softball bats.

"And if a preview of this year's sales is any indication, Missouri ash may be seen around major league ball parks for many years to come. At present, the Amyxes still are mighty happy about landing a sale of 45 dozen bats to the Albany, Ga. club, their first break into the wide Cardinal organization on a large scale.

"They also sold several 'personalized' swatters, with player's individual names on them, to Walter Shannon, director of the Cards' class B and C Clubs, for distribution as Christmas presents.

"Most of their bats have been used by farm clubs and in spring training so far, but the Amyxes believe 'we're just starting.'

"Recent sales include several miniatures and 10 dozen major bats to the Reds; about 10 dozen to the Dodgers; miniatures to the Pirates; a few dozen majors to the Cubs and Tigers; and four dozen to the Browns. They also style a few cork ball bats and some fungo knockers. All that doesn't count the thousands of dozens of softball bats, their strongest movers.

"But as far as their rolling pin sales go, the Amyx haven't reported any to wives of the more versatile major league players as yet.

Major League wallop packed by thriving West Plains bat factory.

Orin Amyx, left, holds a split log which is destined to become one of the topnotch grades of bats turned out every day by the Amyx Manufacturing Company in West Plains. The firm's best bats come from such logs as these because they're cut according to grain all the time. Wood is dried some nine months before it's ever taken out of storage.

Right, is Truman Joplin, of Joplin Bros. Company, who was 'borrowed' for this picture. He's shown cutting an ash log into squares, next step in the long bat production line. This huge saw, and four others just like it, cut 1,00 logs daily into four squares and readies them for the lathe.

And at left is the old gent himself. He's C. L. Dorsitt, who's been setting automatic lathes for the manufacture of bats for 32 years. Twenty-eight to 30 knives have to be set exactly right on each lathe head. And the process is extremely slow. Dorsitt usually works 'a good day' in setting just one lathe.

One of the busiest workers in this bat-making business is young Jack McCrackin, right,who runs three 'round sticks of wood' a minute through one of the company's powerful lathes. When he finishes with the 'round stick', his machine's 30 knives have turned out a bat you're likely to see around many ball parks this summer. At present, he's working on a 16,000 dozen order for a variety store chain.

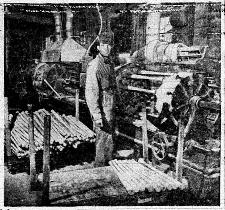

Left is Harold Riley, chief sander for the Amyxes. Riley sands about 10 bats a minute on that intricate machine he's standing in front of, then cuts off the knobs and sands them. Next steps are the homemade branding machine, the dipper, and then the storage room.

Readying one of the Amyx Manufacturing Company's finished products for a bit of pre-season action is Bob Speake, a graduate of Springfield sandlots, who'll be turning in his diamond duties this year for the Springfield Cubs of the Western Association. Speake, a long-ball hitter, played with Carthage of the KOM League last year. He's wielding a 36-inch Ted Williams bat above, one of the company's best-styled knockers.

Find this article at http://thelibrary.org/blogs/article.cfm?aid=4801&lid=0