|

Volume I, No. 2, Winter 1973 |

THE OZARK JOHNBOAT

The Ozarks has many things that are all its own, One of the most interesting products of the Ozarks is the johnboat, a combination of the ingenuity of the people and the natural features of the region. The johnboat is a long, narrow, flat-bottomed wooden boat designed for fishing the pools (called eddies) of the Ozark rivers and floating over the swift shallow riffles. It floats downstream with the current and is paddled by one person in the back using a light-weight paddle.

No one knows for sure when the first johnboat was built or where it got its name, though it is generally agreed that it was first designed by a man named John for float trips on the White River. The same general style boat was used throughout the Ozarks on most streams. Each river had its own boat which was adapted to the characteristic features of that river.

[4]

Not many wooden johnboats are made anymore For they have been largely replaced by inexpensive, easier-to-transport aluminum boats which are produced by the hundreds by several boat industries in the area. These aluminum johnboats are popular; yet, many fishermen familiar with old-time johnboats prefer the wooden ones.

In our desire to record the art of making the wooden johnboat, several BITTERSWEET staff members helped Emmitt Massey build one. He has built many johnboats for floating, fishing and trapping on the river farm where he grew up. He explained more about the boats.

"Originally when they were built, they were built right on the river bank. They were a heavy, durable boat made strictly for floating and fishing Ozark rivers. They were long. I've heard of some as long as twenty-seven feet to haul freight on Current River, but most around here were sixteen to twenty feet. The longer they are the more buoyancy they have. I wouldn't want one less than sixteen feet. They were designed to be stable enough to stand upright in while fishing and to float in four inches of water. They are narrow to go through brush and around log jams. Each boat I make I do it a little different. Many people will disagree with me on building this boat, but this is my way now. Another time I'd make it completely different maybe."

PREPARING THE FLOORING

The first day he spent getting the flooring ready. The lumber he used for the floor was cyprus because it is fairly hard and will resist water. It takes about 50 feet of 1 x 8 boards to lay the floor. If the lumber has waves in it, and won't lie flat, it should be split lengthwise. The boards are then cut into about three Foot lengths. Select only good boards with no cracks to be tongue and grooved.

The tongue to use is a quarter inch tongue. The tongue and groove are used so the floor will fit tightly and securely. When put into the river, the boards will swell up, sealing the floor tightly, thus preventing leaks. Lay aside the flooring while you prepare the frame. Emmitt did his own tongue and grooving because he could not get good enough prepared flooring.

| MATERIALS FOR JOHNBOAT

50 Feet 1 x 8 cyprus for floors, ends and keel |

PREPARING THE FRAME

Sides

Mahogany or redwood are good woods to use for the sides. They are both tough woods that water doesn't effect. Emmitt used mahogany.

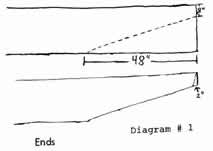

Prepare the two 16 Foot sides by cutting a slope on each end so the front and back of the boat will rise out of the water. This makes the boat much easier to steer. Use the same cut on each end of both boards. (see diagram #1)

Diagram #1

Ends

Before cutting the ends, cut a board 35 inches at the top and 29 inches at the bottom to tack between the two sides in the center so the middle of the boat will be wider at the top than at the floor. This positions the sides of the boat to get the slant needed for the ends. When floor is laid this board is removed.

Diagram #2

Cut two ends 27" by 8" by 25". (see diagram # 2)

Glue and nail the ends to the sides with #6 cement coated nails. It may be necessary to clamp the sides to make it tight.

[5]STEPS IN MAKING A JOHNBOAT

1. After tongue and grooving the flooring, cut the slope on the sides. Glue and nail the ends to the sides tightly, forming the frame of the boat.

2. Waterproof caulking is put into each groove before using that board.

3. Glue the area where floor board is to be placed. Use resin glue.

4. Nail each board securely with #6 cement coated nails, two on top and one nail driven in slanted, just above the tongue.

5. After floor is finished, saw off over hanging boards and sand entire bottom smooth. Fill any cracks with waterproof caulking.

6. The keel will not bend easily so use a weight to pressure the board securely to boat. Use 1 1/4 inch flat head screws to hold the keel tightly.

[7]

7. The inside braces must fit flush to the floor of the boat, and the pieces must fit together tightly. Use screws to secure the 1 x 2 braces.

8. Screw in the braces for the seat. Use 1 x 4's 12 inches long. One set is set against one end, one set in the middle. The third is set 12 inches from the end to allow leg room or a motor if desired.

9. Seats are made from 1 x 12's. Cut them to fit flush to the boat. Screw them tightly.

10. Spray rails are nailed on top. The 1 x 2 boards are set so the insides are flush with the inside of the boat. Bend them with the curve of the boat and nail tightly.

11. Screw in four barn door handles with two on each end. Now paint the boat with marine paint. It will take about two coats of paint for the boat.

LAYING THE FLOORING

The flooring is probably the most time consuming work on a johnboat, not because it is hard, but because there is a lot of it.

The bottom of the boat is sloped. After having laid the sloped edge facing upward, then mix a small amount of waterproof glue and have #6 cement coated nails ready.

Starting at one end of the boat, put glue on the ends and sides where the first tongue and grooved board will be placed. Then place the board so that the tongue faces inward and nail securely. On all the rest of the boards for the floor, a waterproof caulk must be put into each groove to help seal the boat. Use three nails on each board with two driven from the top and one driven slanted lust above the tongue into the sides. Set all of the nails on top in the wood and then fill each hole with wood putty. Many times it is necessary to use a clamp to get the flooring to fit tightly together.

After completing the floor, saw off any overhang and sand the entire boat smooth.

REINFORCING THE ENDS

After sanding the boat, put on reinforcing ends. Emmitt made these of cyprus wood and cut them to cover the entire ends of the boat, covering the ends of the side and flooring boards. (see diagram 3) This piece will be about 29 x 8 !/2 x 27. Glue and then tightly screw these onto the boat. One of the reasons for putting these second ends on is to make a stronger end in case a motor is used.

Diagram # 3

Before placing the keel, check the floor for spaces between the boards. If there are any, then fill them with waterproof caulking and remove excess caulk with a rag soaked in paint thinner.

LAYING THE KEEL

Laying the keel is one of the easier parts of making a johnboat. Take a sixteen foot board four inches wide and lay it down the middle of the underside of the boat. Start at a reinforced end and place screws in a zigzag pattern in every flooring board the entire length of the boat. (see diagram #4) When reaching the middle, someone will have to stand on the keel so it will bend with the curve of the boat. Do not cut the keel into pieces because they might tear off in fast water. The screws must be set-screwed into the wood and the holes filled with wood putty. Then sand the keel smooth.

Diagram #4

SAND AND CHECK FOR LEAKS

Before working on the interior, sand it out thoroughly and fill any places of possible leaks with waterproof caulking

INTERIOR

Braces

The inside braces take a little time. They are 1 x 2 's laid inside the hull of the boat for extra strength at the floor alongside the sides. Because both the front and back slope upward, it is necessary to cut the braces into three parts for each side. Cut the ends of each board so that they fit tightly against each other and the boat. It may be necessary to use a clamp to push the braces tightly alongside the hull. Use number 9 screws, 1 1/4 long to screw the braces in tightly.

Seats

The seats come next. First install the seat braces or supports. Cut six 1 x 4's twelve inches long For braces, two for each seat. Place the first two at one end of the boat, one on each side about one and one-half inches From the top. Using number 9 screws, screw the braces into the sides of the boat. Repeat this at the middle and front of the boat. Then cut the seats out of 1 x 12 's of white pine so they fit tightly to the boat and screw each seat to the brace. One end seat is positioned 12 inches from the end to leave room for a motor if desired, ar if used as the front, to give leg room for facing forward.

[10]

SPRAY RAIL

The boat is almost done, However, the spray rails have to be nailed on. Set two 16 foot length of mahogany 1 x 2 's along the edge of the sides and nail them down. The overhang is on the outside. This strengthens the boat and makes a wider surface to draw the trot line over to keep hooks from catching.

HANDLES

The handles are next. Get four barn door handles, two for each end and screw in securely. These are to help carry the heavy boat.

FINAL FINISHING

Plane and sand off square edges on bottom, keel and tip rail especially.

After complete sanding, the boat is ready to paint. Use at least two coats of good quality marine paint to help seal the outside of the wood to prevent leakage and protect the wood. A periodic painting will increase the life of the boat.

Before putting the boat into the river, fill the bottom with water for a few hours to allow the wood to swell together.

The Ozark johnboat is ready for many hours of relaxing float fishing.

THE FINISHED JOHNBOAT

Diagram # 5

Diagram # 6

[11]

Copyright © 1981 BITTERSWEET, INC.

Next Article | Table of Contents | Other Issues