The Cotton Mill

The Cotton Mill- An institution in which all our people are interested-What is being done now and the prospects for the future.

Missouri Weekly Patriot, May 11, 1876

"While much has appeared in our columns from time to time relative to the Springfield Cotton Mill, since the first inauguration of the enterprise, it may prove of interest to many to learn something of the present status of the concern under the new regime. It is unnecessary to enter into a description of the structure, of its appointments, or review its past history. As to the first it speaks for itself, and stands a monument to the enterprise of those of our capitalists who, seeing the wants of the city, and the necessity of a bold stride towards manufactories, at a most critical financial period stepped to the front and put their means into what will eventually prove one of the most important institutions of its kind in the state. The results are also familiar to all. The Mill was run for a year or so, and then sold under the hammer, proving, financially, a poor investment to those who had put their money into it. Fortunately, indeed, for us, its purchasers were among those of our citizens whose interests are identified with the growth and prosperity of the city. Having made the purchase, they determined at once to demonstrate that they had not invested in an elephant and to this end secured the services of Mr. J. P. Baliey of Auburn, N. Y., a practical man, whose large experience in extensive cotton mills in the east well fitted him for the undertaking. Mr. Bailey arrived some three months since, and began preparations at once. He found the roof of the building in a worthless condition, and the machinery rusty from idleness, and very much out of repair from ill usage. It took some time to get things straightened out, but he finally announced himself prepared for business, and the machinery was manned with a competent force. The familiar whistle again woke the echoes, telling of the accomplishment of a victory over discouraging and seemingly insurmountable obstacles, and congratulations were tendered the new management upon every hand.

"While much has appeared in our columns from time to time relative to the Springfield Cotton Mill, since the first inauguration of the enterprise, it may prove of interest to many to learn something of the present status of the concern under the new regime. It is unnecessary to enter into a description of the structure, of its appointments, or review its past history. As to the first it speaks for itself, and stands a monument to the enterprise of those of our capitalists who, seeing the wants of the city, and the necessity of a bold stride towards manufactories, at a most critical financial period stepped to the front and put their means into what will eventually prove one of the most important institutions of its kind in the state. The results are also familiar to all. The Mill was run for a year or so, and then sold under the hammer, proving, financially, a poor investment to those who had put their money into it. Fortunately, indeed, for us, its purchasers were among those of our citizens whose interests are identified with the growth and prosperity of the city. Having made the purchase, they determined at once to demonstrate that they had not invested in an elephant and to this end secured the services of Mr. J. P. Baliey of Auburn, N. Y., a practical man, whose large experience in extensive cotton mills in the east well fitted him for the undertaking. Mr. Bailey arrived some three months since, and began preparations at once. He found the roof of the building in a worthless condition, and the machinery rusty from idleness, and very much out of repair from ill usage. It took some time to get things straightened out, but he finally announced himself prepared for business, and the machinery was manned with a competent force. The familiar whistle again woke the echoes, telling of the accomplishment of a victory over discouraging and seemingly insurmountable obstacles, and congratulations were tendered the new management upon every hand.

"Calling at the mill a few days since, with a view of ascertaining any facts that might prove of general interest, we found Superintendent Bailey engaged in overseeing the repair of some piece of machinery. Making known our desires as best we could amid the Niagara din which greeted our ears from the moment of entrance, the Superintendent extended a cordial greeting and after stepping into the office to leave an order with his daughter, who keeps the books of the establishment, placed himself at our disposal. Never having been through a cotton mill while in operation, it was decided to take in the entire process, from the time the raw material is unbaled, until it is worked up into cotton yarn and sheeting. Entering the second floor of the L, [ell] the visitor is introduced into the room where the cleaning process is conducted. It is surprising to observe the amount of seed, dirt, etc., extracted from the cotton, which, to an inexperienced observer, appears clean enough in its bale. This is only accomplished after a passage through five separate machines, at the last of which it is wound up in rolls as white as snow, leaving in its track a waste of refuse, and presenting a pleasing contrast to the matted masses being taken form the bales at the other end of the apartment. From this room the rolls are taken to the carding and spinning department which occupies the entire second and third floors of the main building. Here is presented a hive of industry. Every available foot of space is occupied by machinery under the charge of neatly attired females. Everything is like clock-work, all seeming to know their duty, and intent upon preforming it. It would prove an impossibility in a brief newspaper article to give an intelligent account of the cotton from the time it enters the carding machines, on the second floor, until it leaves the third floor for the weaving department, in large rolls of fine white thread. The intricate and delicate machinery, and the variety of processes bewilders the uninitiated looker-on. It is sufficient to know that is done, and well done. The weaving department and drying room is located on the first floor. Of the latter we have but little to say. It is a gratification to observe the accurate working of the handsome machinery, but the young man who oversees it, in his shirt sleeves and bare feet, in a constant temperature of one hundred and ten degrees, is not a fit subject of envy. In the weaving room the rattle and clash of twenty-four looms greets the ear, and here the results of all the other departments are summed up. In one corner of the room the sheetings are carefully cleaned, folded, weighed, branded and baled.

"At present the company is only making sheetings and cotton yarns. They expect, however, in a few days to begin the manufacture of batting. Of sheetings they are turning out about 2,000 yards per day. This finds a ready market, and realizes from 5 to 8 ½ cents per yard. Of cotton yarns they make four numbers, viz. 9, 10, 11 and 12. The demand for this is greater than their present ability to supply, notwithstanding from 100 to 500 pounds are being manufactured daily. From twenty to thirty bales of cotton are consumed each week.

"The following gentlemen comprise the Board of Directors: T. U. Flanner, President; Chas. Sheppard, Treasurer; H. W. Werth, Secretary; C. E. Harwood, John McGregor and J. A. Dittrick. Mr. Bailey has the general supervision of the establishment and devotes to it his entire time and attention. His assistants in the management are Mr. Jno. Pitcher, of Auburn, N. Y., foreman of the carding and spinning department, Mr. Jno. McElroy, foreman of the dressing department, and Mr. Jas. Kershaw, foreman of the weaving department. This latter gentleman was in the employ of the old company. The number of employees on the pay roll is about seventy, mostly females. They are paid as a rule, by the piece, and earn from two to five dollars per week.

"We can see no reason why success should not crown the efforts of the present company to put the Mill on a paying basis. The Superintendent informs us that the building is in every way adapted to its uses, and that the machinery, which originally cost upwards of $70,000, is of the latest and most approved patterns. Add to this the fact that labor is as cheap here as anywhere, that the raw material grows at our very doors, and that there is a ready local market for every pound of manufactured goods, it would seem that, with judicious management, there is nothing to prevent its becoming permanent in its benefits to the proprietors and our city."

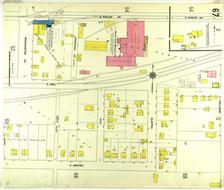

It is not clear what became of the cotton mill. The June 20, 1924, Republican reports the molding department of the United Iron Works company burned but the "old pre-Civil war cotton mill, adjoining the destroyed building on the southwest and used as the pattern storage department" was saved. The Sanborn Fire Insurance map shows the United Iron Works buildings, above, around 1910. The pattern storage building is identified as the smaller pink building just below (south of) the main building (also pink). Comparing the 1872 bird's-eye view map at the top of this article to the 1910 image Sanborn map at the bottom of the article, it would seem the "ell" of the building was gone, perhaps to accommodate the railroad tracks. A 1933 Sanborn map shows the Cotton Mill still standing and being used as a warehouse but subsequent updates to the map in the late 1940's show no buildings on the site. CMC Recycling, 634 E. Phelps Street, now occupies the area.

Find this article at